Recommended products for food safety

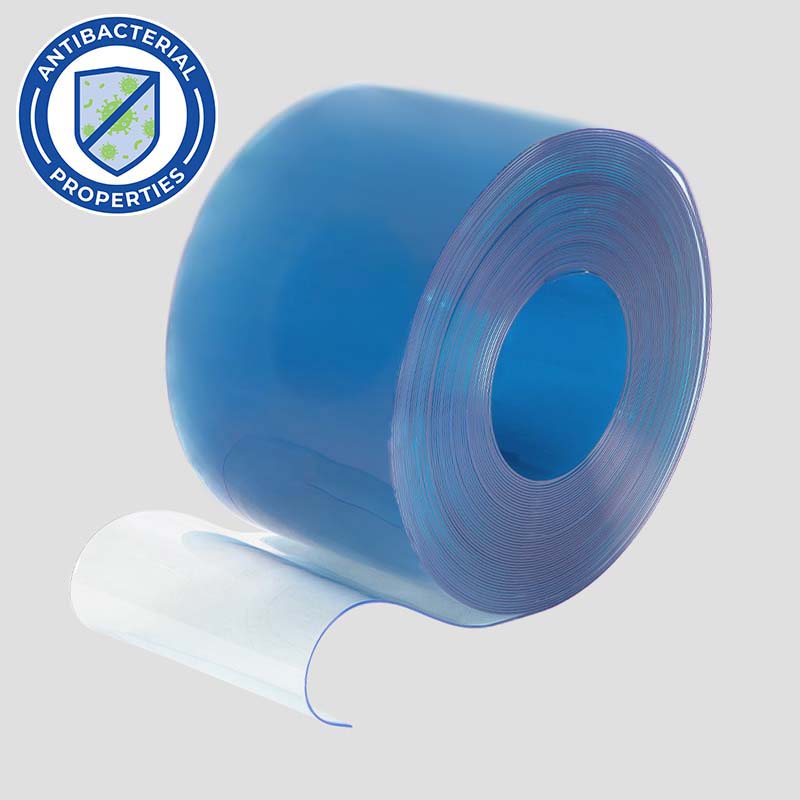

Anti-Bacterial PVC Rolls

Flexible PVC rolls with antibacterial properties. Antibacterial PVC has antibacterial properties and is perfect for workplaces where germs and bacteria are a major concern, such as hospitals, laboratories or food processing factories.

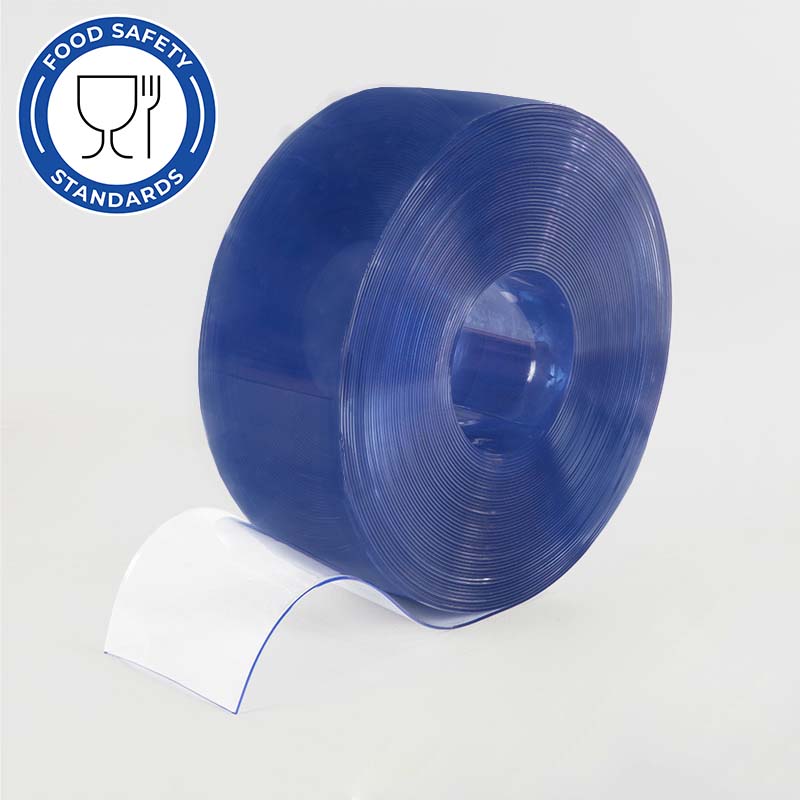

SelectFood Grade PVC Rolls

Specifically designed for food contact and safety. Food grade has specifically been creating with certain technical aspects to ensure it complies with food safety.

SelectAntibacterial PVC Sheets

Flexible PVC sheets with antibacterial properties. Antibacterial PVC has antibacterial properties and is perfect for workplaces where germs and bacteria are a major concern, such as hospitals, laboratories or food processing factories.

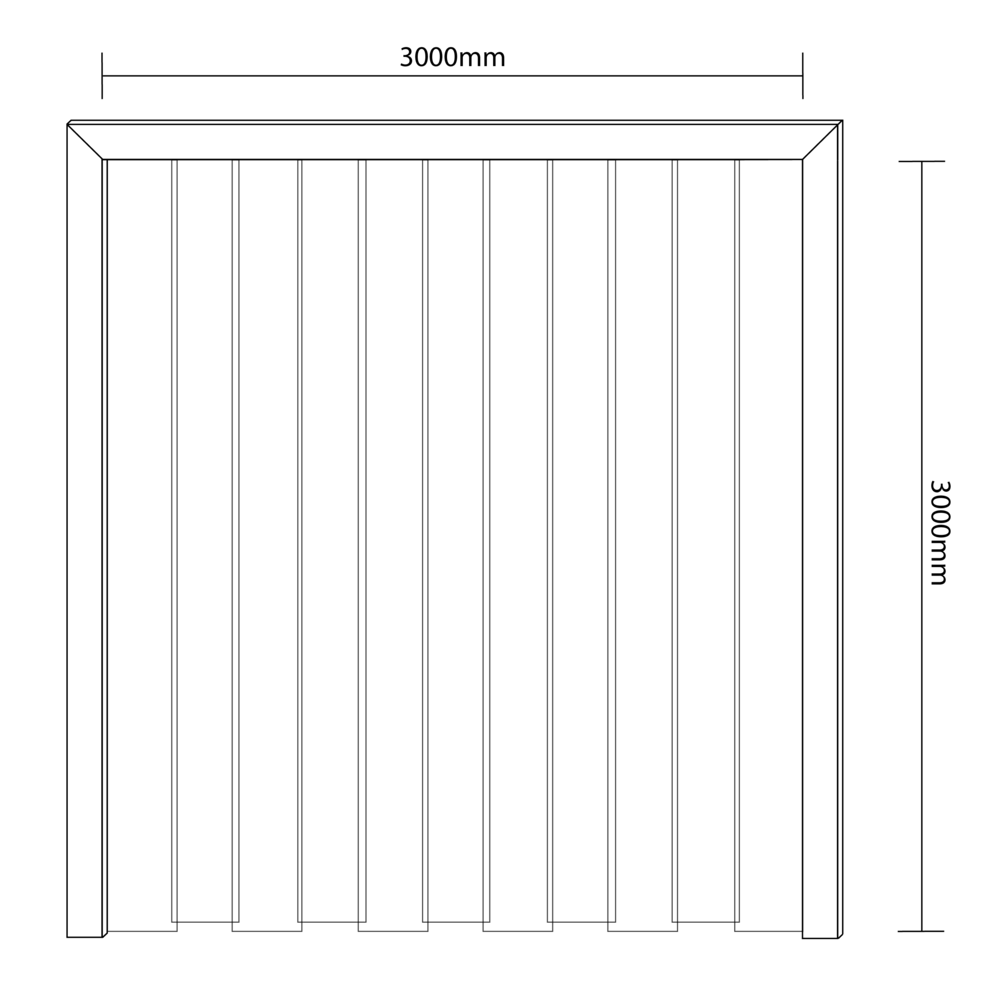

SelectAntibacterial PVC Curtain

Build your own custom Ribbed PVC curtain. Antibacterial PVC has antibacterial properties and is perfect for workplaces where germs and bacteria are a major concern, such as hospitals, laboratories or food processing factories.

SelectCreate a custom PVC strip curtain to suit your needs

Save yourself time and create your own bespoke curtain from our strip curtain calculator. This will give you the opportunity to create a complete custom curtain which will be made to measure here at our warehouse.