Home >Is PVC Food Safe? A Complete Guide to Food-Grade PVC >Is PVC Food Safe? A Complete Guide to Food-Grade PVC

Is PVC Food Safe? A Complete Guide to Food-Grade PVC

When it comes to food safety, the materials used in packaging, storage, and processing equipment play a crucial role. Polyvinyl chloride (PVC) is a common plastic found in food-related applications, but is PVC food safe? This guide will break down everything you need to know about food-grade PVC, its safety standards, benefits, and best practices for maintaining hygiene.

In this guide, we will answer the following:

- What makes PVC food-grade?

- Is PVC safe for food contact?

- How can I clean and maintain PVC used in food environments?

What Is Food-Grade PVC?

Understanding PVC as a Material

PVC (Polyvinyl Chloride) is a synthetic plastic polymer known for its durability, flexibility, and resistance to chemicals. While most standard PVC contains dangerous plasticizers, stabilizers, and additives that may not be food-safe, food-grade PVC is specially formulated to meet safety standards for direct food contact.

What Makes PVC Food-Grade?

Food-safe PVC is manufactured without harmful additives like phthalates, lead, or BPA, ensuring it doesn’t leach toxins into food or beverages. It must comply with FDA (Food and Drug Administration) and EU food safety regulations, making it safe for food handling, storage, and packaging applications.

Key Features of Food-Grade PVC:

- Non-toxic composition (free from harmful plasticizers and phthalates)

- Chemical resistance (won’t react with food or cleaning agents)

- High durability (withstands temperature variations)

- Non-porous surface (prevents bacterial growth)

Is PVC Safe for Food Contact?

Regulations and Certifications

For PVC to be considered food-safe, it must meet strict regulatory guidelines:

- FDA Compliance – In the US, food-grade PVC must meet FDA 21 CFR 177.2600 standards for food contact materials.

- EU Food Safety Standards – In Europe, food-safe plastics follow EU Regulation 10/2011, ensuring they don’t release harmful substances.

- NSF Certification – Many food-processing facilities require NSF (National Sanitation Foundation) certified PVC, indicating it’s safe for water and food applications.

Types of Food-Grade PVC Applications

Food-safe PVC is commonly used in:

- Food processing conveyor belts

- Flexible tubing for beverage and dairy industries

- PVC food wrap (cling film)

- PVC strip curtains for food storage areas

Benefits of Using Food-Grade PVC

- Chemical and Stain Resistance:

PVC is resistant to oils, fats, and acids, making it ideal for food environments. Unlike porous materials, it doesn’t absorb stains or odors.

- Durability and Longevity:

Food-grade PVC is tough, impact-resistant, and has a long lifespan, reducing maintenance costs.

- Easy to Clean and Maintain:

A smooth, non-porous surface makes PVC easy to clean, preventing microbial growth and contamination.

- Cost-Effective Alternative:

Compared to materials like stainless steel, PVC is more affordable while still maintaining high hygiene standards.

How to Properly Clean PVC in Food Environments

Best Practices for Cleaning Plastic Surfaces

Maintaining hygienic PVC surfaces is crucial in food storage and preparation areas. Here are the best practices for cleaning PVC surfaces effectively:

- Use Food-Safe Cleaners – Avoid harsh chemicals that may degrade PVC. Use mild detergents or vinegar-based solutions.

- Sanitize Regularly – Disinfect with diluted bleach (1:10 ratio) or an FDA-approved sanitizer. Be wary about using bleach as it can permanently damage the PVC if the solution is too concentrated.

- Avoid Abrasive Scrubbers – Use soft cloths or non-abrasive sponges to prevent scratching the surface.

- Ensure Proper Drying – Wipe PVC dry to prevent moisture buildup, which can harbour bacteria.

How to Clean Plastic Curtains in Food Storage Areas

- Dust and debris removal – Wipe with a damp microfiber cloth.

- Deep cleaning – Use a mixture of warm water and mild detergent.

- Disinfection – Spray with a food-safe sanitizing solution.

📌 Related: How to Clean PVC Strip Curtains in Food Storage Areas

Common Myths About Food-Grade PVC

🔸 “All PVC is food-safe”

❌ Unfortunately not. Only PVC that meets FDA and EU regulations is safe for food contact.

🔸 “PVC releases toxic chemicals into food?”

✅ Food-grade PVC is formulated without harmful additives, ensuring it doesn’t leach chemicals.

🔸 “PVC isn’t durable enough for food processing.”

✅ High-quality food-grade PVC is resistant to heat, moisture, and chemicals, making it highly durable.

How to Choose the Right Food-Grade PVC for Your Needs

When selecting PVC for food-related applications, consider:

- Certifications: Look for FDA, NSF, or EU-compliant

- Durability Needs: Choose rigid PVC for structural use and flexible PVC for tubing or wraps.

- Temperature Resistance: Ensure the material withstands food processing conditions.

💡 Pro Tip: If you need PVC for commercial kitchens or food factories, make sure to use established flexible PVC manufacturers with all the required food safety certifications such as Clearway Online or Extruflex.

Is PVC the Right Choice for Food Safety?

PVC can be a safe, reliable, and cost-effective option for various food-related applications when chosen carefully. Food-grade PVC, specifically designed for food contact, is free from harmful additives like BPA, phthalates, and lead, ensuring it meets strict health and safety standards. It complies with FDA, EU, and NSF regulations, making it a trusted material for food packaging, processing, and storage. Additionally, its durability, chemical resistance, and non-porous surface help maintain hygiene, prevent bacterial growth, and simplify cleaning. When properly maintained, food-safe PVC provides a long-lasting, efficient solution for businesses that prioritize food safety and operational efficiency.

Key Takeaways:

- Always ensure that the PVC has certifications such as FDA, NSF and EU certifications.

- Use food-safe cleaners to maintain hygiene.

- Choose the right type of PVC for your specific needs.

By understanding what makes PVC food-safe, you can make informed decisions for food processing, storage, and packaging.

What Are Food-Grade PVC Strip Curtains?

Food-safe PVC strip curtains are flexible, transparent plastic strips designed for use in environments where hygiene and temperature control are crucial. They are commonly found in:

- Walk-in refrigerators and freezers

- Food processing facilities

- Restaurant kitchens

- Supermarkets and grocery storage areas

Unlike regular PVC curtains, food-grade PVC strip curtains meet strict health and safety regulations, ensuring they do not contaminate food products.

Why Are Food-Safe PVC Strip Curtains Important?

1. Preventing Contamination & Maintaining Hygiene

One of the biggest risks in food storage and processing is cross-contamination. PVC strip curtains act as a barrier, preventing the spread of dust, dirt, and airborne pathogens between different sections of a facility.

- Stops insects, dust, and debris from entering food storage areas

- Reduces bacterial growth by keeping humidity and moisture levels stable

- Minimizes exposure to contaminants when doors are frequently opened and closed

2. Temperature Control and Energy Efficiency

Food processing plants and cold storage rooms require strict temperature regulation to ensure food remains fresh and safe. PVC strip curtains help maintain consistent temperatures, reducing energy loss when doors are opened.

Key Benefits:

- Prevents cold air loss in walk-in refrigerators

- Helps maintain consistent ambient temperatures

- Reduces energy consumption by up to 40% in refrigerated spaces

3. Enhancing Workflow Efficiency

PVC strip curtains allow workers to move easily between different areas without having to open and close doors, streamlining operations.

- Faster access = Increased productivity

- Reduces unnecessary door handling

- Keeps food storage areas easily accessible

- Improves workflow efficiency in busy kitchens

How to Choose the Best Food-Grade PVC Strip Curtains

When selecting PVC strip curtains for food environments, consider the following factors:

1. Thickness and Durability

The thickness of PVC strips affects durability and insulation properties.

- Standard thickness (2mm – 3mm): Ideal for light-duty areas

- Heavy-duty thickness (4mm – 5mm): Suitable for high-traffic food storage rooms

2. Transparency and Visibility

Clear PVC curtains provide high visibility, allowing workers to see through them and preventing accidents in busy kitchens or storage areas.

💡 Tip: Choose ribbed PVC strips for areas with heavy forklift or cart traffic to reduce wear and tear.

3. Temperature Resistance

For cold storage and freezers, low-temperature PVC strip curtains are essential.

- Standard PVC: Works well in temperatures as low as -10°C

- Polar PVC: Designed for freezers and deep freeze areas (-40°C and below)

4. Anti-Microbial & Non-Toxic Properties

For enhanced food safety, choose anti-microbial PVC strips, which prevent the growth of bacteria and mold.

- BPA-free, lead-free, and phthalate-free PVC

- Anti-static and non-stick properties for easy cleaning

How to Clean and Maintain Food-Safe PVC Strip Curtains

To ensure hygiene and longevity, regular cleaning of PVC strip curtains is necessary. Follow these steps:

- Remove loose dirt and dust using a soft microfiber cloth.

- Wash with mild soap and warm water (avoid harsh chemicals).

- Use a food-safe disinfectant spray to eliminate bacteria.

- Dry thoroughly to prevent moisture buildup.

Pro Tip: For heavy grease buildup (common in restaurant kitchens), use a vinegar-based cleaner to break down oils while keeping the material food-safe.

Where Are Food-Grade PVC Strip Curtains Used?

Commercial Kitchens:

- Keeps pests out

- Helps separate food preparation zones

- Improves ventilation

Cold Storage & Freezer Rooms:

- Reduces temperature loss

- Prevents frost build-up

- Saves energy

Food Processing Plants

- Separates clean and contaminated zones

- Prevents cross-contamination

- Maintains strict hygiene standards

Supermarkets & Butcher Shops

- Creates a sanitary barrier between fresh food and customers

- Keeps cold air in refrigerated display areas

Are PVC Strip Curtains Safe for Food Environments?

Yes! Food-grade PVC strip curtains are an effective and affordable solution for maintaining hygiene, temperature control, and food safety compliance. Whether used in cold storage rooms, processing plants, or commercial kitchens, they help reduce contamination risks, save energy, and improve workflow efficiency.

Ready to upgrade your food storage facility with food-safe PVC strip curtains? Ensure you choose certified, high-quality PVC and PVC suppliers to meet food safety regulations and maintain optimal hygiene. Thankfully, you’ve come to the right place. Clearway has a food safe PVC strip curtain range that is completely food safe. Purchase these directly on our website or contact us today and we’ll help you with your order!

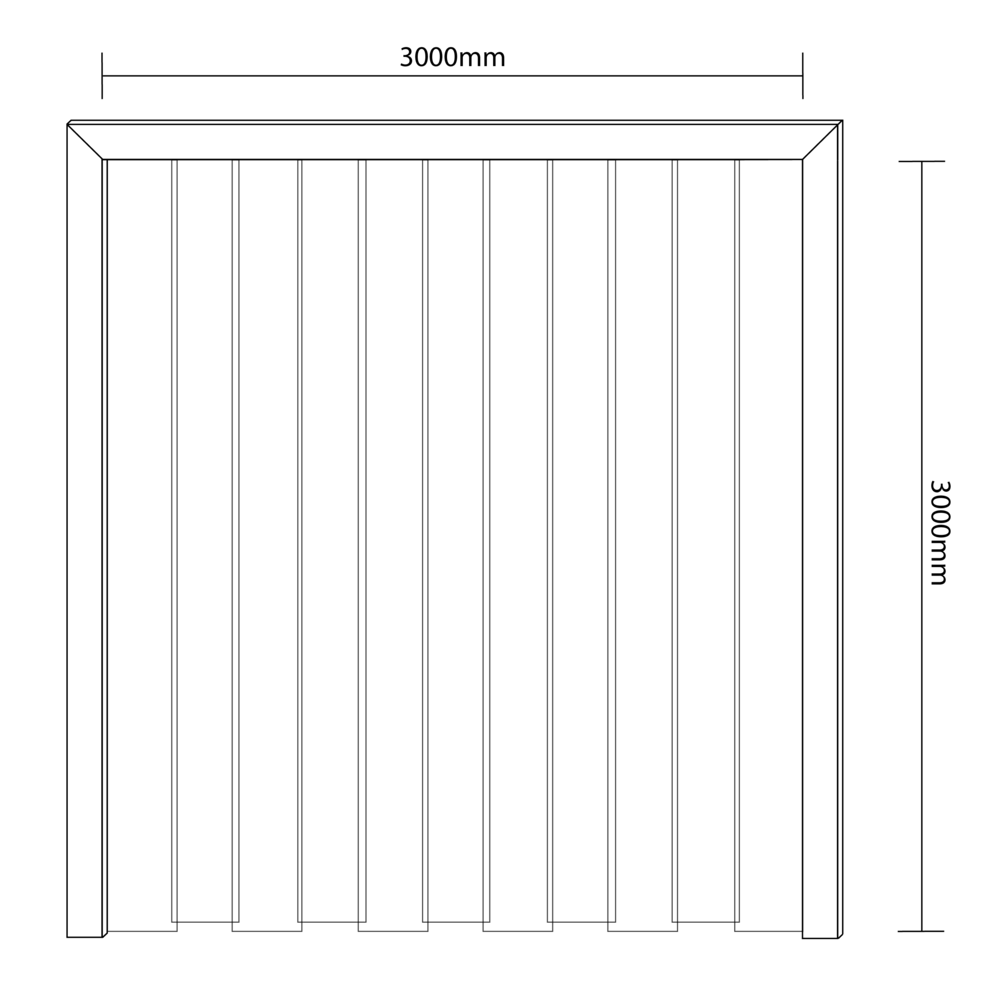

Build your own PVC Strip Curtain and recieve an instant quote!

Save yourself time and create your own bespoke curtain from our strip curtain calculator. This will give you the opportunity to create a complete custom curtain which will be made to your measurements and shipped to you within a few days.